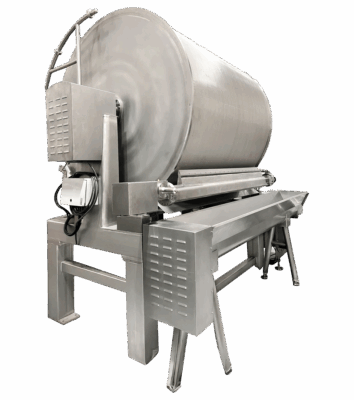

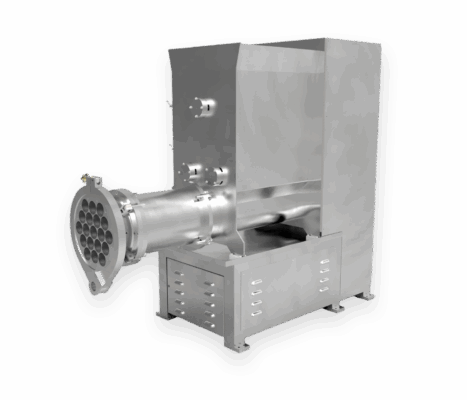

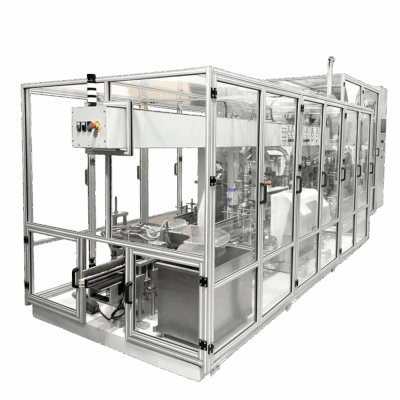

Yeast Production Machines

As Corist, we design and manufacture the basic machinery needed in wet and dry yeast production lines with high engineering standards. Our hygienic and durable systems that increase process efficiency consist of the following main equipment: